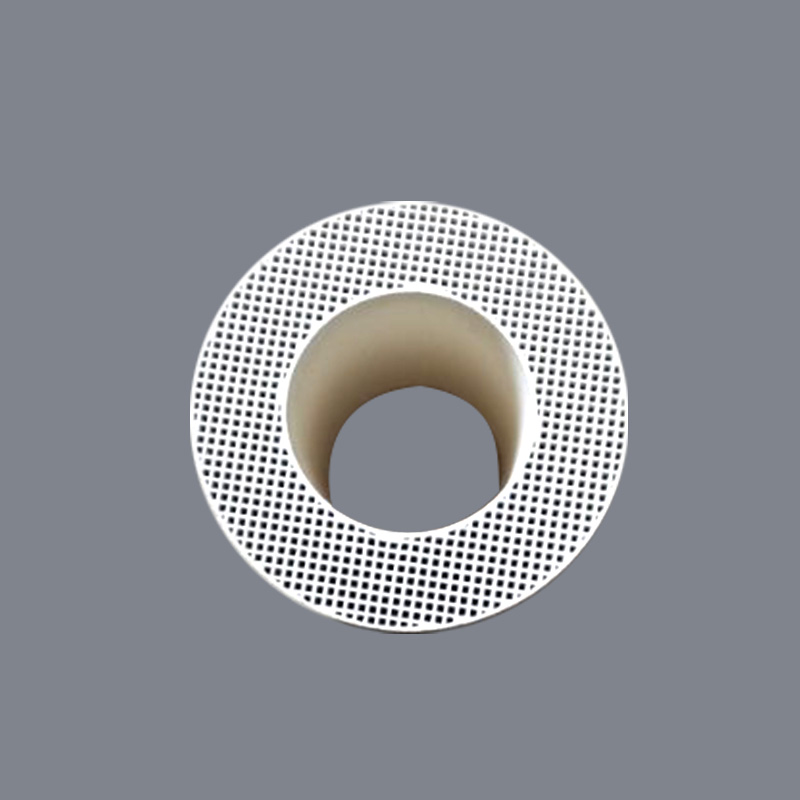

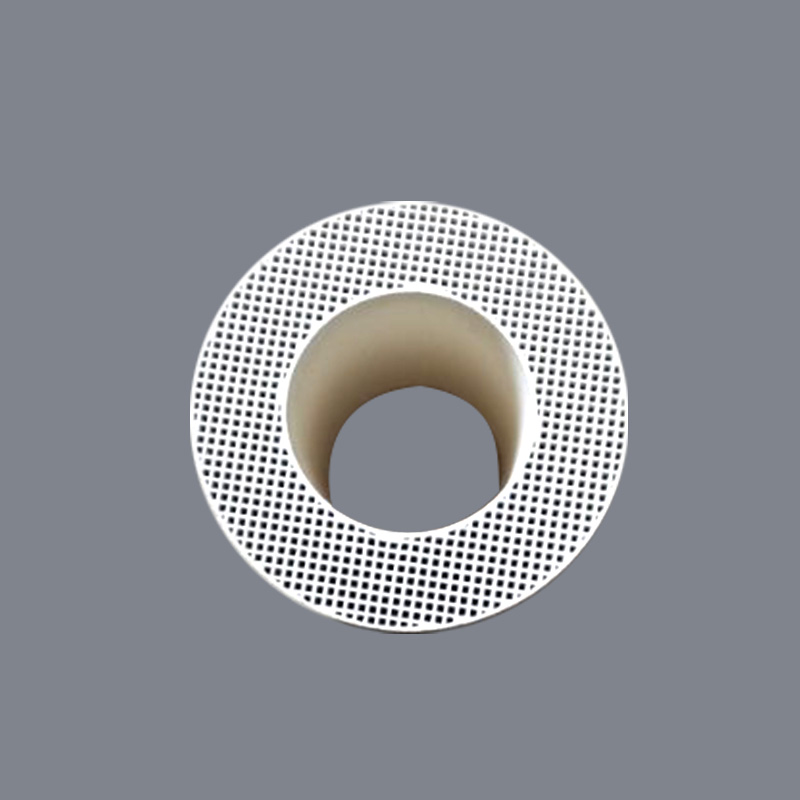

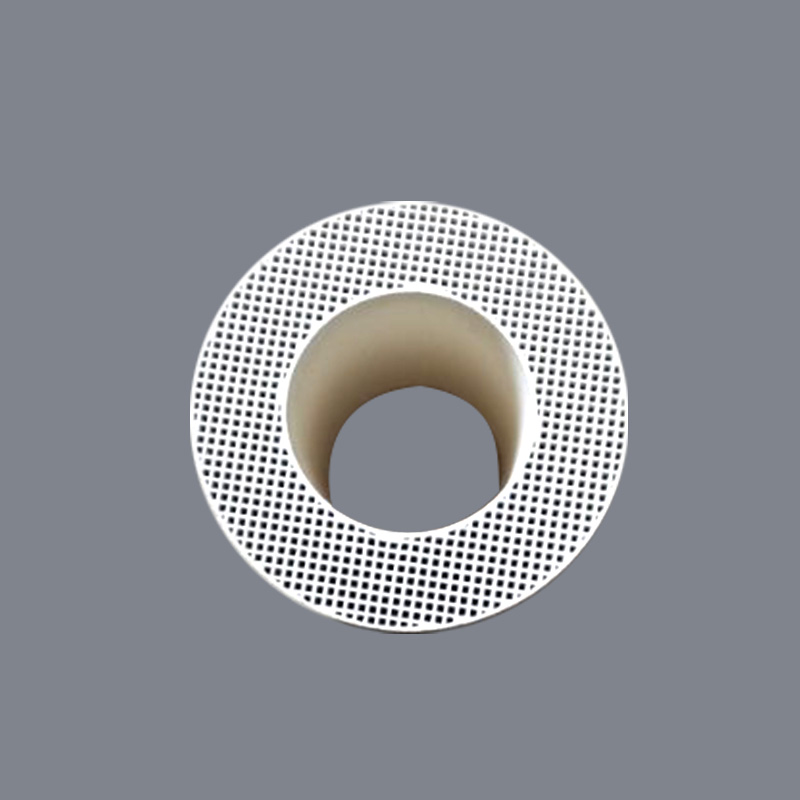

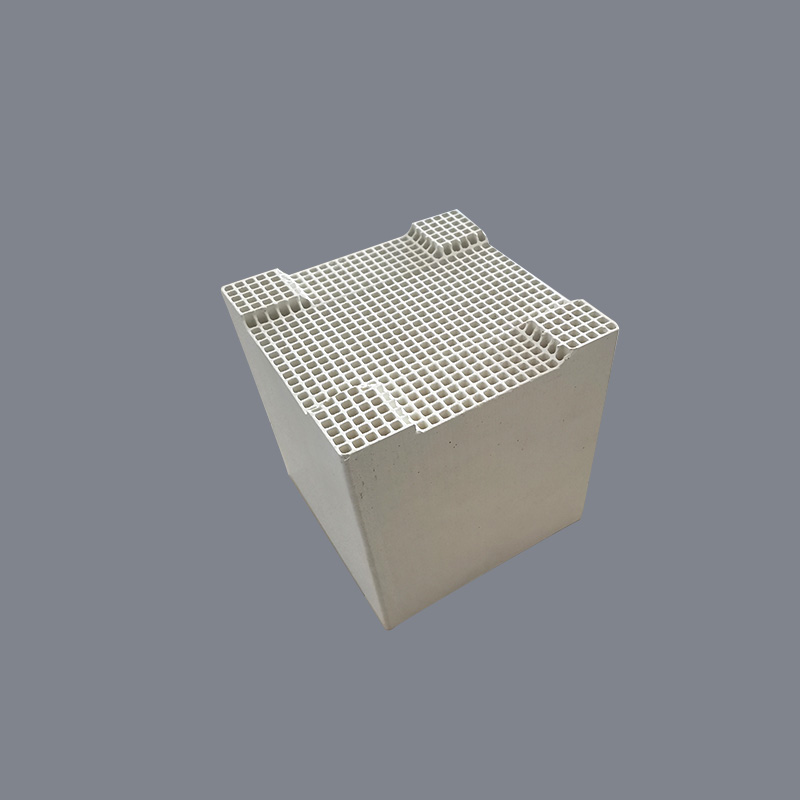

HTAC is a huge energy saving and environmental protection dual efficacy burning technology. Honeycomb ceramic regenerator also known as the ceramic regenerator, ceramic honeycomb body are the key components of regenerative burner, it is widely used in iron and steel, machinery, building materials, petrochemical, non-ferrous metal smelting and other industries of various key furnace, step into furnace, heat treatment furnace, ladle and tundish baking equipment, forging furnace, melting furnace, soaking pit, radiant tube burner, bell type furnace, blast furnace hot blast stove, the oil and gas boiler. Various ceramic kilns and glass kilns in building materials industry; various tubular reheating, cracking and other industrial furnaces in the petrochemical industry. The technology is through the commutator device to make two regenerative heat alternating absorption and release heat, effectively limit the recovery of the heat of the flue gas, and then the combustion-supporting air and gas in the furnace heating to more than 1000℃,even low calorific value of poor combustion can also achieve stable ignition and efficient combustion, can save fuel up to 40-70℃. By increasing the yield more than 15℃, the oxidation loss of steel embryo is reduced by more than 40%, N02 emission is less than 100pm, and the emission temperature of flue gas is less than 150c, which greatly reduce the greenhouse effect of the earth atmosphere. If HTAC technology is adopted in the most industrial kilns in the country, its economic and social benefits are immeasurable, which will greatly alleviate the energy shortage and improve the living environment of human beings.